Workflow

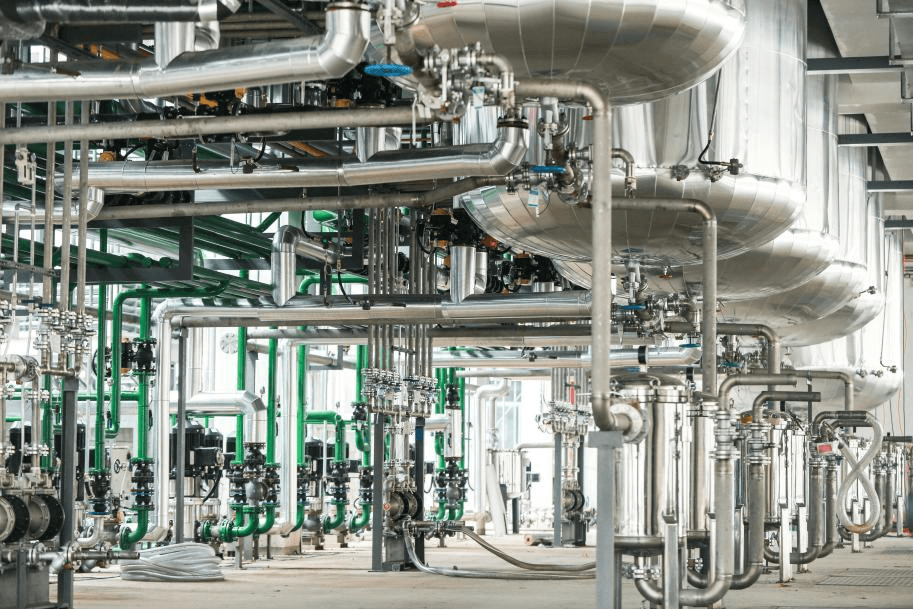

Produce adhesive

We produce both water-based and solvent-based pressure sensitive adhesive, formulated according to advanced high quality adhesive technologies. With precise control over polymerization and material ratios, our adhesive reactors ensure stable performance, strong bonding, and excellent durability.Our interior adhesive production capability allows us to customize formulations to meet different application needs, providing a solid foundation for high-quality, high-performance adhesive tapes.

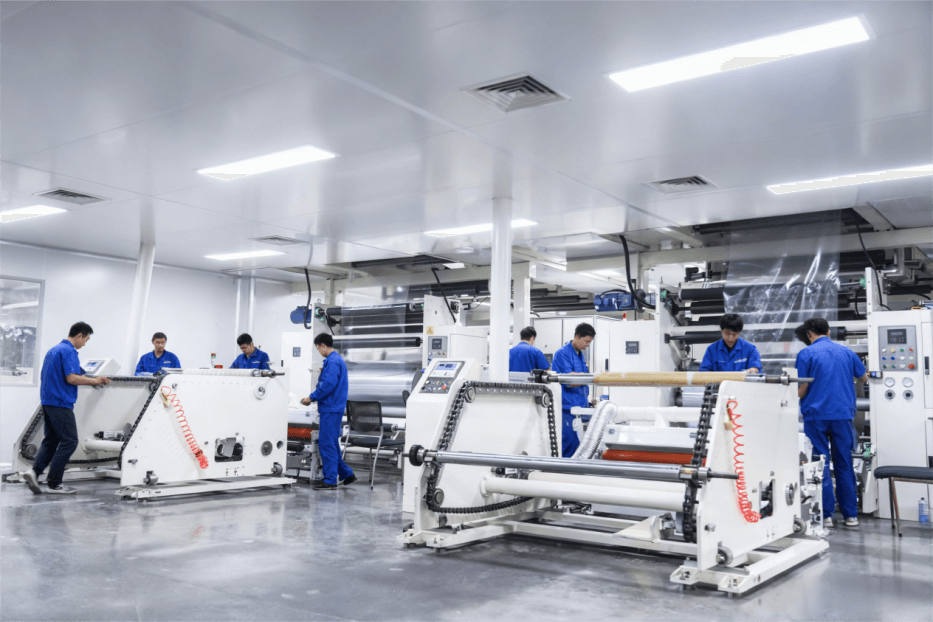

Coating

Coating lines are the core of adhesive tape production, precisely coating adhesive to PET, foam, or tissue bases. With advanced coating technology and automated control, we ensure uniform thickness, stable adhesion, and consistent quality. Offering solvent-based, water-based, and natural rubber processes, we meet diverse industry needs with high efficiency, reliability, and sustainability.

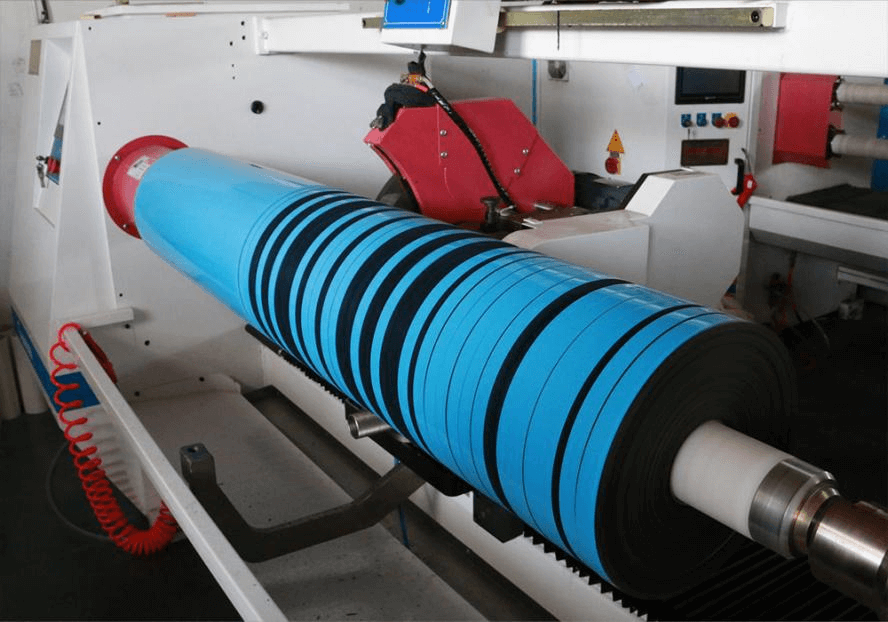

Slitting

Slitting and rewinding are essential processes in adhesive tape manufacturing. Tapes can be slit and rewound according to customers’ specific size and specification requirements. With advanced technology and strict quality control, we offer flexible slitting and rewinding services that ensure precise dimensions, excellent roll formation, and reliable performance for different adhesive tape applications.

Transportation

We provide efficient and reliable logistics solutions to ensure timely and secure delivery of our products worldwide. We work with trusted logistics partners to offer multiple shipping options, including air, sea, and express delivery, allowing flexibility based on customer needs. With professional export experience and strict tracking management, we guarantee smooth, on-time transportation and worry-free service from our factory to your destination.